About Us

About Us

We are working on the development, designing, producing and marketing of powder processing equipment and production line. Guilin Hongcheng has more than 70 patents, has the right of export, and is certificated by ISO9001:2015 international quality management system is a national high-tech enterprise. Depending on the producing and researching experiences of decades, Guilin Hongcheng has become a major powder processing equipment manufacturer and export base.

Hongcheng factory is organized by three production bases and a researching center. The main production center locates in Yangtang Industrial Park, Xicheng Economic Development Zone, Guilin, spread an area of 170,000m2. The HC Series Grinding Mill, HLMX Ultra-fine Vertical Mill, HLM Vertical Mill, HCH Ultra-fine Mill and Special Material Grinding Mills (including coal mills, bentonite mills, HCT17 titanium dioxide ultrafine mill, etc) are famous products and best sellers. Our operation principle is to bring the greater value for customers by quality and service. We are not only producing and selling productions, but also provides customers with scientific and reasonable overall solutions and one-stop satisfactory services from experimental research, process scheme design, equipment manufacturing and supply, organization and construction, after-sales service, parts supply, skill training, etc., so as to help you achieve success in your projects.

At present, Hongcheng is entitled to a high fame in domestic powder processing field. No matter in infrastructure construction, mineral deep processing, solid waste cyclic utilization, energy saving, emission reduction, environmental protection, or metallurgy, construction material, chemical engineering, power plant fields, we can see the brand of Hongcheng; no matter in the fields of large-scale non-metallic ore pulverization, marble processing, environmentally friendly desulfurization limestone preparation, bentonite preparation, petroleum coke pulverization, Hongcheng is the first choice of customers. Our vision is to establish a global brand for China, we are holding the principle of ‘Quality is the basement of survival, service is the source of development’. The facilities and service of Guilin Hongcheng have been spread to Vietnam, Laos, Malaysia, Indonesia, Sultan, South Africa, Russia, Philippines,Egypt, Brazil, etc.

Who we are?

Hongcheng offers an extensive range of grinding mill, we have grinding equipment including Raymond mill, vertical mill, superfine, ultra-fine grinding mill and others. We own a high reputation in domestic powder processing field. No matter in infrastructure construction, mineral deep processing, solid waste cyclic utilization, energy saving, emission reduction, environmental protection, or metallurgy, construction material, chemical engineering, power plant fields, we can see the brand of Hongcheng in the fields of large-scale non-metallic ore pulverization, marble processing, environmentally friendly desulfurization limestone preparation, bentonite preparation, petroleum coke pulverization.

What we do?

Guilin Hongcheng Mining Equipment Manufacture Co., Ltd.

—–Professional supplier of powder processing complete solution in China.

—–R&D Base of Super-large Grinding Mill

Guilin Hongcheng Mining Equipment Manufacture Co., Ltd. is a leading enterprise of powder processing equipment in China, which is the professional supplier of grinding mill equipment integrated solution. Our company working on the development, designing, manufacturing and marketing of powder processing equipment and production line. Our main products include Raymond mill, vertical roller mill, ultrafine mill and so on, the ultimate product fineness can achieve 80-2500 mesh freely.

Hongcheng factory is organized by three production bases and a researching center. The main production center locates in Yangtang Industrial Park, Xicheng Economic Development Zone, Guilin, spread an area of 170,000m2. The HC Series Grinding Mill, HLMX Ultra-fine Vertical Mill, HLM Vertical Mill, HCH Ultra-fine Mill and Special Material Grinding Mills (including coal mills, bentonite mills, HCT17 titanium dioxide ultrafine mill, etc) are famous products and best sellers. Our operation principle is to bring the greater value for customers by quality and service. We are not only producing and selling productions, but also provides customers with scientific and reasonable overall solutions and one-stop satisfactory services from experimental research, process scheme design, equipment manufacturing and supply, organization and construction, after-sales service, parts supply, skill training, etc., so as to help you achieve success in your projects.

Why choose us

Strong R&D Strengthen

We adheres to the scientific research and development strategy focusing on improving product competitiveness, relies on a strong scientific research team, develops and innovates, and continuously improves the overall scientific and technological innovation ability of the enterprise. Our grinding mills are made of superior quality, as we keep developing and using advanced technologies to assure quality and performance to control best grinding result.

Strict Quality Control

1. production plan

To ensure that the product can be delivered on time and be qualified, our equipment production follows the following plan:

1.1 After the contract comes into effect, we will immediately communicate technical exchanges with the buyer, and provide the buyer with relevant information about the equipment within three days after the contract comes into effect to ensure that the buyer can complete the process design and on-site civil construction in time.

1.2 The planning department prepares the contract execution letter according to the contract, arranges the purchased parts, and informs the production department to organize production.

1.3 The finished products are packaged in the finished product warehouse after passing the quality inspection by the quality inspection department.

1.4 Before delivery, the planning department shall prepare the delivery list, arrange the transportation vehicles and prepare equipment documents as required.

1.5When install and debug the equipment, the after-sales service personnel should fill in the product feedback form in time, and the company should evaluate each department participating in the production according to the product feedback, and proposes suggestions for improvement.

2. Quality control plan

Quality is the basis of survival, our eternal service purpose is customer-oriented. Advanced products must with excellent product quality assurance as the premise, excellent product quality is the basis for the consideration of users. In order to further strengthen product quality management, establish the concept of “quality first”, and ensure product quality, our company has established a complete quality management system.

Quality Target

2.1 All products quality must reach the standard value, the rate of control is 100%. the unqualified one will pass.

2.2 unqualified product are not allowed to delivery, and the party concerned shall be subject to economic punishment.

3.Material procurement control

3.1 All material procurement must fully know the market information, on the premise of ensuring quality, and take price into account, to establish a long term business relationship with the supplier.

3.2 For all the material supply contracts, the supplier shall provide relevant quality certificates and testing documents and data, and we the reserve the right to prosecute the supplier’s product quality.

3.3 For the first cooperation with the new supplier, the provide technical data must be re-examined and tested, and it can be used when qualified.

4.Process control

4.1 During the process of product processing, our company has set up multiple quality control points to evaluate the product processing process according to the quality assessment rules. Unqualified products are strictly prohibited from entering the next process.

4.2 The quality assessment rules of all products are strictly implemented in accordance with ISO standards, national standards, industry standards and corporate standards. The plates are in accordance with GB700-88, the painting is in accordance with JC/T402-91, and the welding rod is in accordance with GB981-76. Implement JC/T532-94 standard.

Workshop & equipment

Guilin Hongcheng is an ISO 9001:2015 certified company and owns more than 60 patents, which is a national level high-tech enterprise. Our factory has three production bases and one researching center which covers an area of 170000 square meters. We have a total of over 800 employees, among them, there are 110 R&D personnel at present. Our equipment has been sold to over 150 countries with the amount of more than 5000 sets.

In 2013, Guilin Hongcheng grinding mill long-distance intelligent monitoring system was set online, which can monitor the operation situation of the facility 24h/day. We are committed to the construction of marketing network including complete machine sales, parts supply, after-sales service and market information, we have established more than 30 offices in domestic and formed a sales and service network. At the same time, Hongcheng has actively opened up foreign service points and established many offices in Vietnam, Malaysia, Indonesia, South Africa and so on.

Our hot selling mills mainly including HC series Mill, HLMX superfine vertical Mill, HLM vertical Mill and HCH ultra-fine Mill. Our business philosophy is to create the maximum value for customers by offering the optimal quality and service. We not only produce and sell products, what’s more, we provide customers with scientific and reasonable complete solutions to help customers get the best grinding effect.

Company technical strength

Relying on the mining equipment R & D center, Guilin Hongcheng has continuously increased investment in scientific and technological R & D and talent training. It has successively established technical cooperation and academic exchange relations with domestic colleges and universities and scientific research institutes, keeping up with the forefront of the times and constantly injecting new vitality.

Guilin Hongcheng is a scientific and technological enterprise specializing in the R & D and production of mine grinding equipment. Guilin Hongcheng has established a research institute in cooperation with the scientific research institute, which is committed to the major subject of comprehensive automation and large-scale of mine grinding equipment.

Guilin Hongcheng company not only pays attention to scientific and technological research and development, but also has been committed to introducing advanced machinery manufacturing technology in the industry. In 2008, we cooperated with many German companies to introduce advanced milling machine manufacturing technology into China and become an excellent brand of domestic mining equipment.

DEVELOPMENT

Guilin HongCheng Mining Equipment Manufacture Co., Ltd. was founded in 1999, which is a high-tech enterprise specializing in the production of grinding mill equipment. Adhering to the scientific management mode of modern enterprises, Guilin HongCheng has become a well deserved advanced enterprise in the domestic machinery manufacturing industry with exquisite workmanship, forge ahead, development and innovation and rapid rise.

Our Team

Guilin Hongcheng has a total of over 800 employees, among them, there are 110 R&D personnel at present. Our research and develop (R&D) center was founded in 2005, it has been engaged in the research of mining equipment technology and complete equipment, and development of new products, our company has a number of product patents. We continue to increase investment in scientific and technological research and development and personnel training, and have established research institutes and academic exchange relations with various domestic universities and research institutes.

Corporate culture

Guilin Hongcheng ranks among the best in the field of mining machinery grinding equipment, which comes from its responsibility to the society. Guilin Hongcheng is responsible for society, employees and customers, and realizes the sustainable development of the enterprise!

Responsibility to customers:

We adhere to the principle of “customer first and service first”, strive to provide customers with all-round, personalized and professional products and services, and maintain customers’ trust and loyalty with high-quality products and services.

Responsibilities to employees:

Guilin Hongcheng attaches importance to the learning and promotion of employees and the protection of health and welfare. We provide employees with a healthy working environment and atmosphere, so that employees can be rewarded in Guilin Hongcheng and continuously improve their quality of life.

Social responsibility:

As an ambitious company, Guilin Hongcheng has always fulfilled its obligations to the society and is committed to contributing to China’s economic growth and social development.

Hongcheng has set up a public welfare fund to fulfill its corporate responsibilities in environmental protection public welfare, education public welfare and Red Cross public welfare.

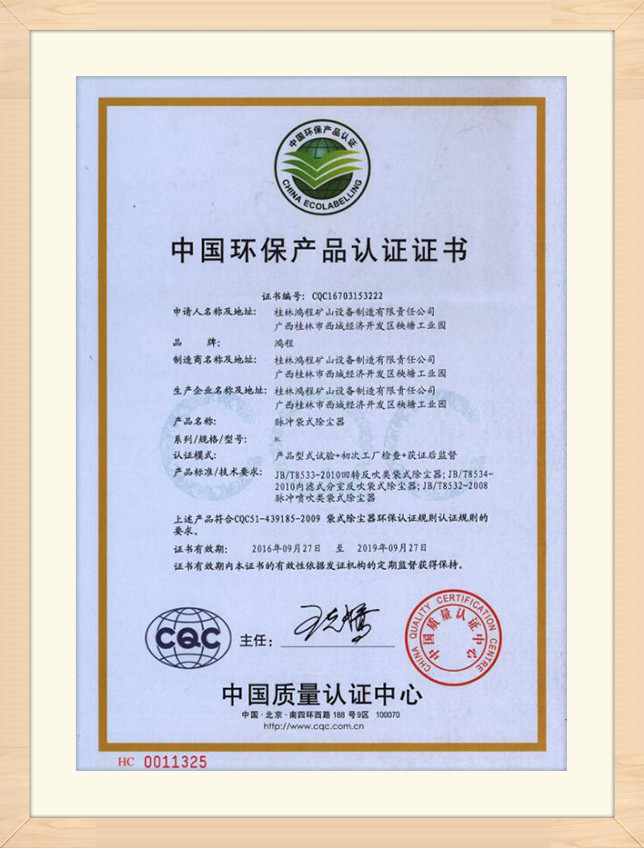

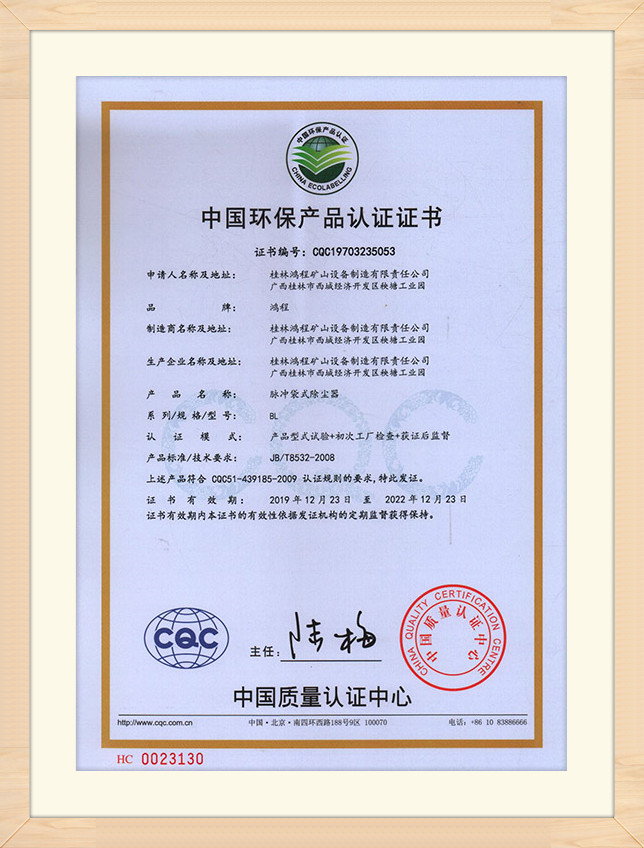

–HCM Brand Qualification Honor

–International Co-Operation

–Project Cases at Home and Abroad

–R & D